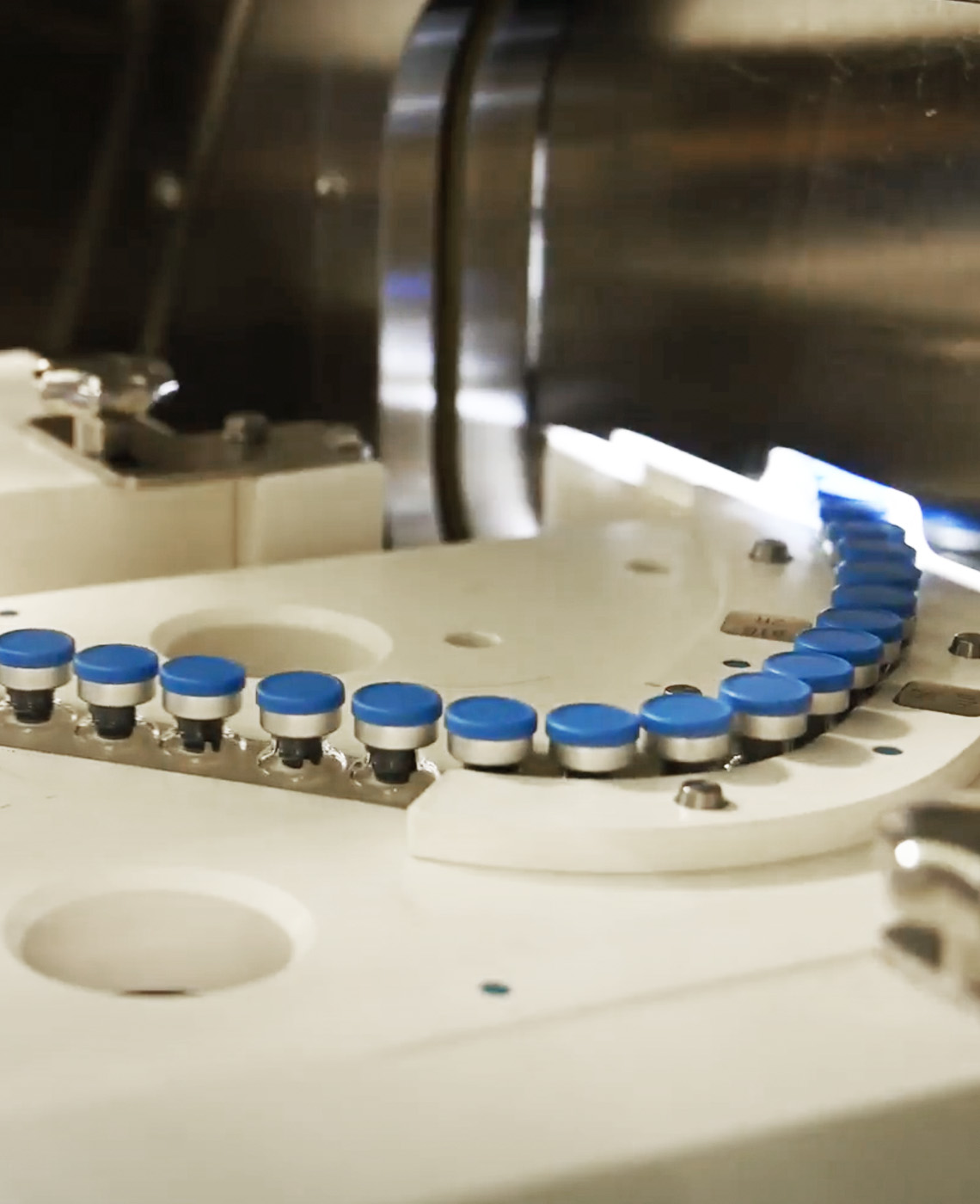

Lyophilized Vials

INNOVATIVE APPROACHES FOR LYOPHILIZATION

We have considerable expertise in the process of lyophilization, which enables product stability and improved shelf life. Utilizing their extensive knowledge of biologics and small molecules, the scientists at our Lyophilization Center of Excellence have devised innovative approaches for optimizing formulation and cycle times for freeze-drying. These customized methodologies are used to convert liquid products into lyophilized form to produce the final product contained in the vial.

LYOPHILIZED VIAL MANUFACTURING FEATURES

VIAL SIZES

2 mL to 100 mL volume

13 mm to 20 mm opening diameter

LIQUID FILLING MECHANISMS PRIOR TO LYOPHILIZATION

Rotary piston

Peristaltic

Sensor-based time/pressure

FINISHING

Manual, semi-automated or automated inspection

Bulk and secondary packaging

RELATED RESOURCES

Bringing your Sterile Injectable Product to Market: Considerations for Collaborating with a Fill/Finish CMO

Bringing your Sterile Injectable Product to Market: Considerations for Collaborating with a Fill/Finish CMO - CMO Selection, Request for Proposal (RFP) Delivery, Proposal Review, and Project Award.

View resourceVial Breakage During Lyophilization

Learn more from the BioPharma Solutions team on the Root Causes and Mitigation Strategy for Vial Breakage during Lyophilization.

View resourceSimtra Biopharma Solutions Capacity Update October 2023: Biologics

Simtra BioPharma Solutions (Simtra) is a premier CMO with a singular focus on sterile injectable drug product form/fill/finish services.

View resource